Automatic Sludge Blanket Level Detector

Get in touch! How can we help you with your water and wastewater sampling needs?

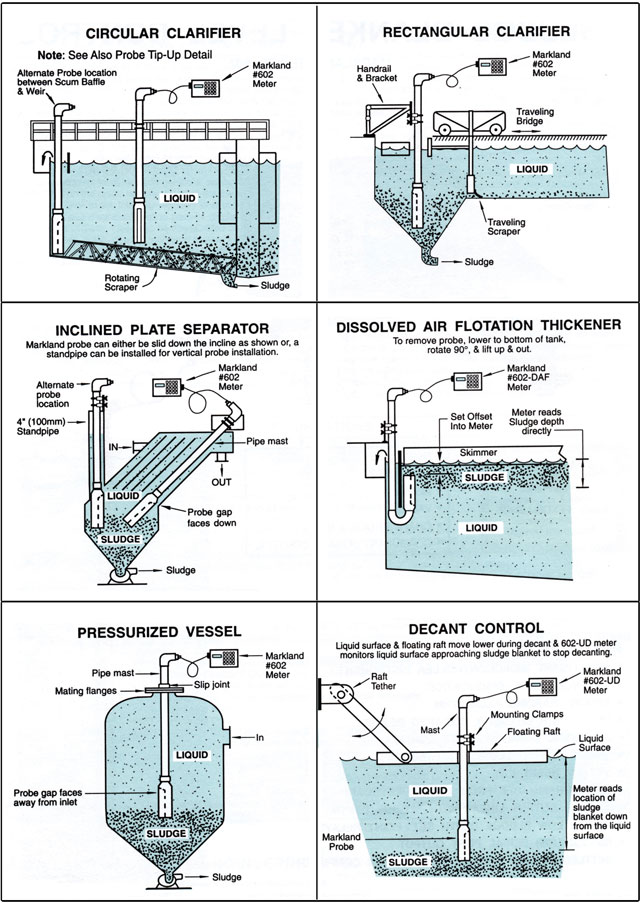

Markland’s Automatic Sludge Blanket Level Detector is used wherever liquids are separated from solids. With its sensors automatically adjusting to accommodate thick or thin concentrations, the detector tracks the liquid-solids interface level as it rises and falls. By entering two independent set-points (high and low), operators program underflow pumps to operate only when necessary to maintain preferred sludge levels, helping to prevent process upsets such as septic sludge conditions and carryover, and to maximize water removal. A LCD readout is provided. Its slim profile and use of infrared light make it ideal even for use in obstructed or constricted areas.

Automatic Sludge Blanket Level Detector — Get the Markland Advantage

Measure, monitor and control the sludge bed depth

- In diverse clarification processes: silt, sludge or biosolids in primary and secondary clarifiers, backwash sludge from sand or membrane filters, resin beds in intake water softeners, settled mud levels in tanks, settled fly ash from scrubbers, and more.

Meet the needs of your unique water and wastewater application

- Slim profile and high-intensity infrared light are ideal for obstructed or constricted areas, such as inclined plate lamellas.

No calibration required

- Beam intensity of the LED/phototransistor sensors automatically adjusts to accommodate thick or thin biosolids concentration and even light flocs.

Complement other treatment processes

- In DAF units, the detector can adjust surface skimmer speeds to match variations in the thickness of the floating sludge layer. In SBRs, it can control the decant valve to minimize cycle times.

Automate underflow pumps to maintain preferred liquid-solids interface levels

- Help prevent carryover.

Optimize silt or sludge feed density for enhanced dewatering

- Maximize water removal. Avoid pumping large volumes of thin sludge. Improve outflow for reuse.

Reduce energy use, wear-and-tear on pumps, and downtime for maintenance

- Program desludge pumps to run only when necessary rather than at timed intervals.

Get answers when you have questions

- Technical assistance is factory-direct from the designers and manufacturers of this sludge blanket level control equipment.

Automatic Sludge Blanket Level Detector – Get the Markland Advantage

Measure, monitor and control the sludge bed depth

- In diverse clarification processes: silt or biosolids in primary and secondary sludge, backwash sludge from sand or membrane filters, resin beds in intake water softeners, settled mud levels in tanks, settled fly ash from scrubbers, and more.

Meet the needs of your unique water and wastewater application

- Slim profile and high-intensity infrared light are ideal for obstructed or constricted areas, such as inclined plate lamellas.

No calibration required

- Beam intensity of the LED/phototransistor sensors automatically adjusts to accommodate thick or thin biosolids concentration and even light flocs.

Complement other treatment processes

- In DAF units, the detector can adjust surface skimmer speeds to match variations in the thickness of the floating sludge layer. In SBRs, it can control the decant valve to minimize cycle times.

Automate underflow pumps to maintain preferred liquid-solids interface levels

- Help prevent carryover.

Optimize silt or sludge feed density for enhanced dewatering

- Maximize water removal. Avoid pumping large volumes of thin sludge. Improve outflow for reuse.

Reduce energy use, wear-and-tear on pumps, and downtime for maintenance

- Program desludge pumps to run only when necessary rather than at timed intervals.

Get answers when you have questions

- Technical assistance is factory-direct from the designers and manufacturers of this sludge blanket level control equipment.

The Automatic Sludge Blanket Level Detector is used wherever solids are separated from liquids, tracking the liquid-solids interface level as it rises and falls, and automating underflow pumps.

It measures, monitors and helps control the clarification of:

- drinking water and sewage at Municipal treatment plants

- raw influent, effluent and process slurries at Industrial plants.

Applications include:

- inclined plate clarifiers / lamella separators

- gravity settlers

- sedimentation basins

- decanting tanks / decanting control

- dissolved air flotation (DAF) tanks (floating bed)

- sequential batch reactors (SBR)

- batch processes

Markland Automatic Sludge Blanket Level Detector installations can be found in a diversity of treatment, processing, and manufacturing operations, including:

- mineral

- chemical

- pulp-and-paper

- food

- petrochemical

- pharmaceutical

- power generation

- mining

- and more

This versatile instrument detects materials as varied as:

- silt, sludge and biosolids in primary and secondary clarifiers

- backwash sludge from sand or membrane filters

- resin beds in intake water softeners

- settled mud in tanks

- settled fly ash from scrubbers

- metal hydroxide precipitate

- and more

- LED beam automatically adjusts its intensity to detect settled sludge blanket and supernatant interface levels in thick or thin sludges, or in light flocs

- sludge level interface detection is not distorted by the inclined plates of lamella separators

- advanced self-diagnostics

- high intensity infrared beams

- automatic beam intensity control

- 4 – 20 ma output linear with sludge interface level depth

- high & low sludge blanket depth set-point relays

A vertical Probe, submerged in the settlement tank, contains 64 infrared high intensity LEDs stacked vertically, which shine horizontally across a probe gap to 64 phototransistor detectors. This gap contains either liquid or sludge. The 64 pairs are sequentially scanned to locate the sludge bed. Beam power intensity is automatically adjusted to accommodate different sludge concentrations. This high intensity beam easily penetrates fouling on the probe’s windows, and as long as the solids in the probe gap are high relative to the solids in the scum layers on the windows, the meter continues to read correctly. Eventually, the probe has to be removed and given a wipe with a soft cloth.

Process Control

Automatic desludging yields thicker sludge than timers or manual methods, and reduces sludge disposal or processing cost. A desludge pump can be operated automatically from the Low Set-Point Relay along with a Pump Run Interval Timer, and the High Set-Point used as an alarm for excessive sludge depth. Alternatively, the desludge pump can be turned ON at the High Set-Point and OFF at the Low Set-Point, or the 4-20 ma output can be used for continuous variable speed drawoff. The 4-20 ma output can link the sludge blanket level meter to your computer for centralized process control.

Intelligent Microcontroller

The microcontroller scans the probe elements and locates the sludge bed if there is one, and displays this on the LCD. Any top or bottom offset is automatically incorporated into the reading. Out of range or zero readings are displayed if there is no sludge/liquid interface. Error trap routines identify and reject bad scans. To lessen the impact of short-term events, such as passing ‘clouds’, the controller accumulates a running average of several good scans, which dampens the response and smooths the output. If, after several attempts, the detector cannot obtain good scan data (i.e. broken wire, etc.), then the LCD reads “SIGNAL LOST”, both Relays are de-energized, and the 4-20 ma output goes to zero indicating fault. During a fault condition, the controller continues trying to find good scans and resumes normal operation as soon as good data is obtained. Automatic intensity control adjusts the LED firing power to the correct level for each particular sludge/liquid. Progressive slime buildup on the probe merely results in the instrument boosting its beam power level to the intensity required to shoot through the scum. An advanced self-diagnostic routine permits display of problems right on the detector’s LCD. If site-specific problems require an adjustment of the algorithm, the software can be reprogrammed using the front panel membrane switch.

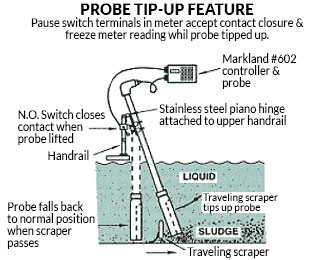

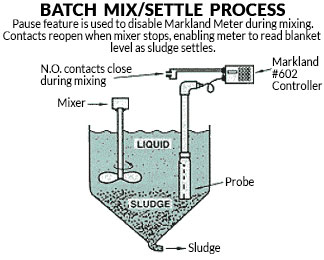

Pause Switch Uses

An externally located switch, with a pair of Normally Open contacts, can be connected to act as a “Pause Switch”. When these contacts close, the Markland transmitter freezes its last reading, and the LCD displays “METER DISABLED HOLDING LAST READING”. This feature is used for a batch mix process to disable the meter during mixing. It is also used to lock out the meter, when the probe is tipped up by a traveling scraper. Both of these uses are illustrated in the accompanying diagrams. When the pause switch reopens its contacts, the automatic sludge blanket level detector waits 30 seconds for the sludge to settle down before resuming normal operation.

Set-point Relays

Two independent set-points (High and Low) are standard. In order to ignore short-term transient sludge ‘clouds’, the actual sludge depth must exceed the set-point for 30 seconds continuously, before the Relay will energize. Similarly, there is a 10-second delay that also must be continuous before the Relay will de-energize. Set-points are entered through the front panel membrane switch and are locked into EEPROM memory, which indefinitely retains the set-point, even during power failure, without requiring backup batteries. The LCD displays the current set-points, which are easily changed using the membrane switch.

Automatic Sludge Blanket Level Detector

| Materials | Probe: PVC Mast: PVC Pipe Clamp: Stainless Steel & Polypropylene Cable: Vinyl Jacketed Enclosure: Fiberglass Body & Clear Plastic Cover |

|

| Dimensions | Probe: | Overall Length: 1330 mm (52¼ in.) Active Element: Length 1219 mm (48 in.) Cross Section: 64 mm (2½ in.) x 38 mm (1½ in.) Gap: 25 mm (1 in.) Mast: 3.5 meters (12ft.), 1 in. Sch. 80, shipped in 3 pieces with fittings |

| Enclosure: | Width 343 mm (13½ in.) · Height 229 mm (9 in.) · Depth 200 mm (7 7/8 in.) | |

| Cable Length | 15 meters (50 ft.) pigtail supplied (measured from top of Probe). Maximum cable length 150 meters (500 ft). Order extra cable separately if pigtail length not sufficient |

|

| Element Spacing | 64 pairs infrared LED/Phototransistor, spaced vertically on 19 mm (¾ in.) centers. Dual Model has 128 pairs | |

| Accuracy | ± 2cm (± 1 in.) | |

| Bottom Offset | Adjustable, 0-700 cm or in. (NOTE: For ‘-DAF’ & ‘-UD’ types this is Top Offset) | |

| Depth Units | Selectable, inches or centimeters | |

| Temperature | Maximum 50°C (120°F) | |

| Power | 110/220 VAC, 220/240 VAC, 50/60 Hz, 24 VDC (advise with order). 15 watts | |

| Outputs | · Liquid Crystal display (LCD) 2×20 Digit Alphanumeric · 4 – 20 ma output signal, linear with sludge interface level · Two DPDT, 5 Amp, Relays, independently adjustable set-points · RS – 232 Serial Port · RS – 485 Serial Port (Optional) |

|

| Models | 602 | Reads sludge depth up from tank bottom |

| 602 – UD | Reads sludge blanket location down from liquid surface | |

| 602 – DAF | Reads sludge/liquid interface in Dissolved Air Flotation thickeners | |

| 602 – LP | Special model for Drinking Water Plant upflow clarifiers where overlying water is very clear & sludge is thin (consult factory for further details) | |

| 602 DUAL & 602-DUAL-UD |

Uses 2 probes, one mounted 48 in. (122 cm) above the other to give 96 in. (244 cm) continous span | |

| Approvals | CSA Approved and CE Conformance |

|

The graphics below demonstrate the Markland Advantage. With Markland’s Automatic Sludge Blanket Level Detector, users can program desludge pumps to run only when necessary to maintain preferred sludge interface levels. This helps to prevent overflows, to avoid pumping thin sludge, and to optimize feed density.

Light Desludging

LIGHT sludge loading can allow a timer to pull a core hole and pump water out the bottom. The Automatic Sludge Blanket Level Detector does not turn on the desludge pump until it is required, and the sludge level is maintained within the high and low set-points.

Timer Desludging

Blanket Level Desludging

Heavy Desludging

HEAVY sludge loading can overwhelm a timer-controlled desludge pump, allowing sludge to slip over the top, while the Automatic Sludge Blanket Level Detector maintains the sludge level within the high and low set-points.

Timer Desludging

Blanket Level Desludging

To receive a quote for a Markland Automatic Sludge Blanket Level Detector, complete the form below.